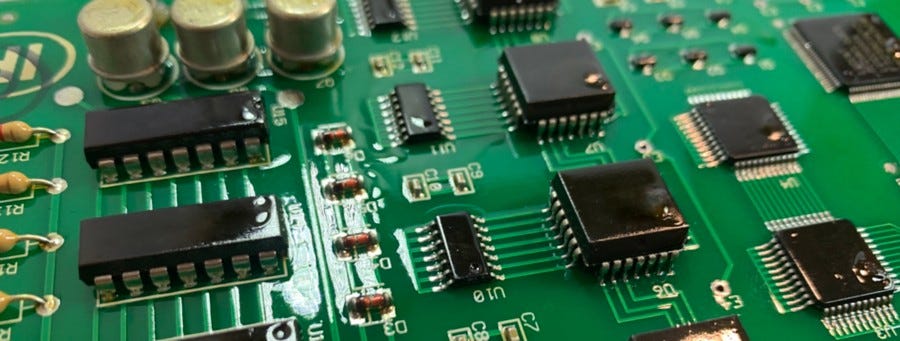

PCB or Printed Circuit Boards are found in all kinds of electronic products today and it becomes the core of their functioning. It becomes important to design the correct prototype of the PCB so that all things can be checked at the right time. Take the help of a PCB factory in China to draw a full design review and judge the quality of the printed board. As the PCBs are being attached to the electronic device, it is important to get the design of the circuit board better.

The selection of the relevant PCB expert or company can be a daunting task if done for the first time. PCBs are everywhere and thus one needs to be selective in getting the right product. Talk with experts who understand the design of circuit boards and thus come up with relevant plans to locate the relevant factory. The PCB factory in China designs the right kind of PCB modules that works with the latest model. Release the electronic product with the right kind of PCBs in it and thus get the design perfect in the first stage.

Let us look at some of the best tips to pick the PCB factory –

· It is important to check the layout design of the PCB. Experts pay critical attention to technical details and thus come up with suitable layouts. A good PCB factory will be able to design the right kind of PCB modules that fit the electronic products perfectly. Make sure that the PCB functions effectively and thus the circuit board manufacturing needs to be done without any issue.

· Check the strategy of the PCB factory. The designs & manufacturing of the PCBs will decide the success of the electronic product and thus you need to pick the best professionals. Talk with the factory professionals and make sure that you have a strategy in place for instant production.

· Check the reputation of the PCB factory in the local market. You’ll get the best assistance from PCB manufacturers and thus check the reputation of the company. A reputed PCB factory will provide the delivery of PCBs at the right time to ensure the release of the final product after assembly.

· Compare the cost of the product across all the available options. Finding the right PCB factory within the budget is a real task and one needs to be aware of the things they need to minimize the cost. Take the help of price quotes to compare the different ranges and come up with the best options.

The PCB factory in China provides

the right kind of options to manufacture circuit boards that function

accurately for products. Picking the correct company for PCB manufacturing can

be a hard task and selecting the right kind of factory becomes important. Take

the help of a good electronic design company and thus get PCBs that work

perfectly for electronic devices. Tackle the issues smartly and thus come up

with suitable solutions.