Without any proper plan, implementing new

PCB products have the tendency to introduce further unnecessary delays and

spending, which could have been easily avoided.

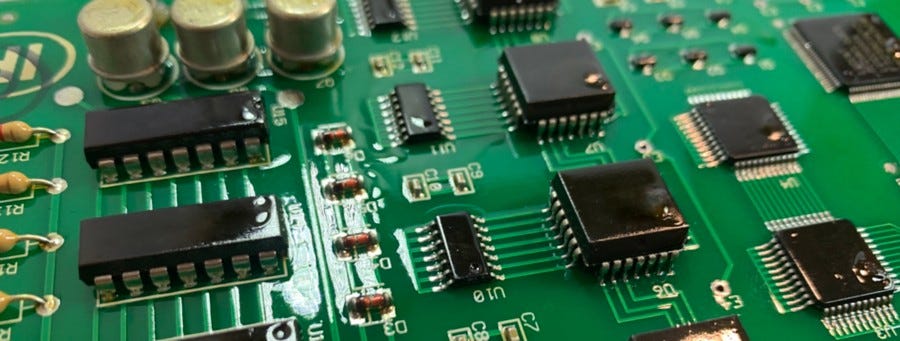

Rapid PCB Prototyping proves to be a useful process when trying to reduce the time needed

for developing new and innovative designs for your business.

What is rapid PCB prototyping?

Before we talk about the benefits of rapid

PCB prototyping services, it is important to know a few basic things about

prototyping. A PCB prototype is an early, demo version of a particular product

built for testing purposes. In simpler terms, prototyping is considered to be

quite an effective method in order to evaluate new innovative design ideas and

seeing if they can be incorporated into the final product or not. Moreover, it

allows the manufacturer to enhance the precision as well as the quality of the

final product.

Now that we know a thing or two about rapid

PCB prototyping, let’s take a look at some of the benefits of rapid PCB

prototyping services.

·

Creative designs:

The more that you seem to know about your design, the more creative you can become. Thorough testing and examination of your product tend to help you come up with innovative and creative ideas that you didn’t come up with before. Furthermore, you would be able to implement all these new ideas practically in a short period of time.

The more that you seem to know about your design, the more creative you can become. Thorough testing and examination of your product tend to help you come up with innovative and creative ideas that you didn’t come up with before. Furthermore, you would be able to implement all these new ideas practically in a short period of time.

·

Several test runs of PCB designs:

With a large number of prototypes available at the ready for verification and testing, you have the ability to get several examinations under distinct conditions and situations in order to assure a certain level of quality of the product, which tends to lead to final top notch products.

With a large number of prototypes available at the ready for verification and testing, you have the ability to get several examinations under distinct conditions and situations in order to assure a certain level of quality of the product, which tends to lead to final top notch products.

·

Test components separately:

One of the major problems faced in advanced projects is that the troubleshooting of several PCB based components can be tough. It can be quite a daunting task to test and verify such models as a single part. However, with the help of PCB Prototype, there is a possibility to have a single prototype for separate components. Having this capability to test and verify each component separately can ease the troubleshooting process significantly.

One of the major problems faced in advanced projects is that the troubleshooting of several PCB based components can be tough. It can be quite a daunting task to test and verify such models as a single part. However, with the help of PCB Prototype, there is a possibility to have a single prototype for separate components. Having this capability to test and verify each component separately can ease the troubleshooting process significantly.

·

Reduced costs:

Detecting certain problems and issues in the PCB model, before you move on to the production phase of the final product, tends to eliminate the risk of losing your money in a final manufacturing process. In addition to this, the prototypes fast forward the testing and verification process, resulting in a shorter time to market and diminish manufacturing costs.

Detecting certain problems and issues in the PCB model, before you move on to the production phase of the final product, tends to eliminate the risk of losing your money in a final manufacturing process. In addition to this, the prototypes fast forward the testing and verification process, resulting in a shorter time to market and diminish manufacturing costs.

So, if you want your business to avoid

losing money and instead avail all the above-mentioned benefits, then it is

recommended for you to turn to rapid PCB prototyping services.